Dry sump so needs a tank FFS, not even thought about this, ordered an original from eBay to get me out of the doo-doo and it’s an ugly beast to say the least…, for some reason it does’nt fit perfectly with how I have changed the layout of the frame, back to the drawing board for me.

So, my thought are now I can make something that does not look so out of place, tucked up under the seat as best we can, space to mount the cdi on top and far enough away from the carbs not to get in the way when we build filters.

Time for some choppy choppy with cardboard and sticky tape, try to get a rough idea of how it might fit and try to get a similar volume or even a bit larger.

I’ve tried to work out volume and think this cardboard mock up is much bigger than it needs to be so I’ll chop it down a bit then make a metal version.

Looks a fair bit different to the original..

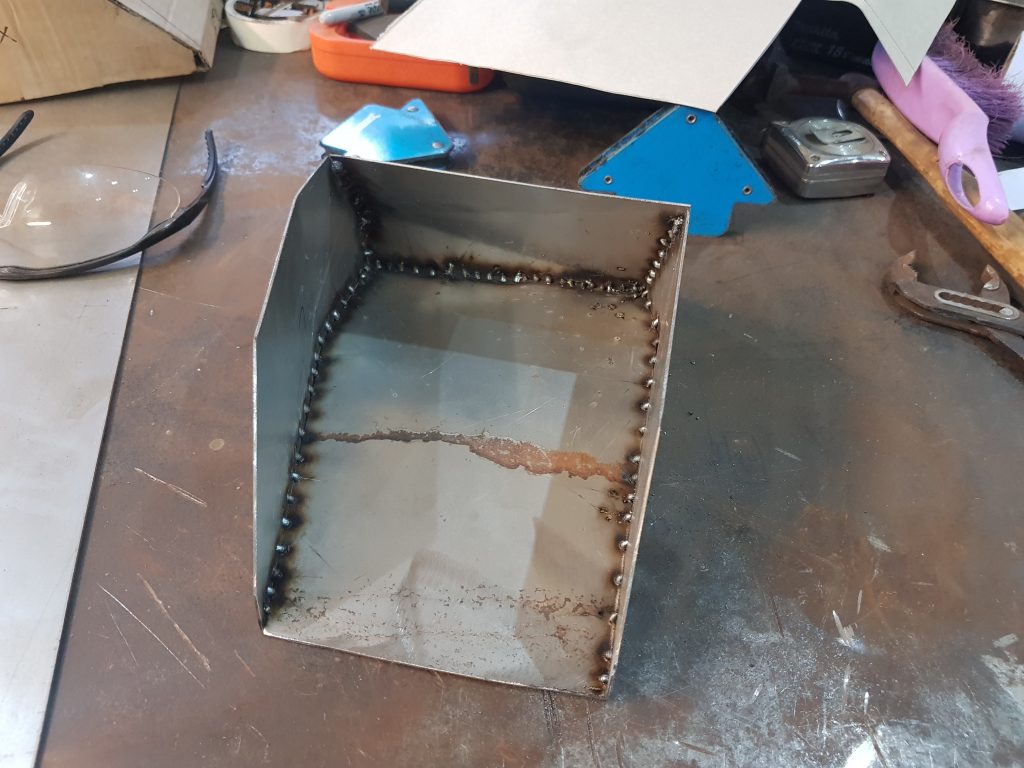

Draw around the box and transfer it to steel plate, I’m using 1.6mm as I have some in stock. I have reduced the size as per the line on the card box. Next we need to bend the plates prior to welding, we use a ‘state of the art’ bending machine to get exact bends.

Ok, so the Scavengers have yet to get a bending machine so we just G-clamp stuff to the bench and whack it with a big hammer, similar results. Next we need to tack the parts together.

The plan is to tack on the inside with the mig welder as it’s quick and easy and when finished seam weld the outside with the tig welder to get an oil tight seal, failing that just get a really thick powder coat….JOKING

Finished up for the night and for some reason I shone my torch back in the workshop…WOW….I have been breathing this in all night, no wonder I get shed bogies.

Next job is to procure an oil feed fitting, the threaded elbow you can see, I am lucky enough to live near some racing companies that stock this sort of thing so this should be easy! OK, not so easy as it turns out, it’s not a standard pipe thread, it’s metric…grrr

I’m loathed to cut up this tank just to get a fitting out and I’m struggling to buy one but… I have just found an M16x1.5 die in my drawer that I bought for some use on the XS project so I can now make one!!

I have bored a 6mm hole all the way through and added the thread just need to make the 45 degree angle.

To make the cut I used the scavengers water jet cutting machine, the burn marks you see on the cut are from water and not where it was G-clamped to the bench and attacked with a grinder by eye in the hope the cut would be somewhere near where we needed it. Yee-Haw..

Once seam welded with the tig and ground off the excess bits it looks alright, need to weld this in place but I’m going to hang fire here a bit as there is some slack in the connecting pipe so I don’t need to commit just yet, I’ll wait untill the cdi is mounted and see how it looks.

Update….so I, for some drunken unknown reason decided to go ahead and weld the elbow in place exactly where it looked like it should go from the bench rather than on the bike….

Looks alright, you can see the long weld closest to camera, this runs in line with the frame so even a stoned monkey could figure out when I add a fitting to the elbow it’s going to hit the bloody frame, one of those moments, all adds to experience though.

Interesting story/fact, when I went to night skool to learn about engineering one of the things that has stuck in my head over the years is something told to me by the tutor (Jack), ‘It’s not a problem making a mistake, it’s how you get out of it that counts.’ wise words from a very clever man.

There is not a lot of room but as it turns out a new 1mm slitting disc in the grinder can just about reach so I started to trim away the welds, went as deep as I dared and then used a large wrench to rotate the elbow to get it free.

Bit of a mess but fixable, thats the beauty of welding, just keep poking in filler wire to cover up your mess!

So we have missed the frame this time, much better, now we need a way to fill the tank, had a rummage around and I’ve found an oil bung from a car, looks new!

Found a rubber ring that fits and quickly whipped up a threaded jobbie on the lathe, turns out the thread is the same as the elbow so I already had a tap to suit, a little rusty but it worked fine.

I’ll weld it in place tomorrow, need to make some kind of drain plug then I can weld the bottom on the tank. I want to add a magnet to the drain plug as I think it’s a great way to get an early warning if something is letting go internaly.

I quite like making exhausts, I was given a crash course by ‘Wolfy’, friend of the Scavengers and an all round decent chap, very creative and tallented more than me, his work with stainless steel is world class but when it come to needlecraft or macrame I’m the boss OVER 60% of the time.

Unfortunately for me, stainless steel is the material of choice for exhausts, can be tricky to get in the size you want and the bends used must be formed using the mandrel proccess. I am in lockdown, mail order is very limited so I am aiming to use whatever I can get my grubby little mitts on, I have a few leftovers and managed to order some bends, it will be fine.

First things first, we need some flange’s, we, the Scavengers love a nice flange, not oversized or rough to look at, a nice tidy flange.

I dont have a way of cutting the middle out so chain drilling holes will do, you just drill in a circle and use a small chisel to join the holes then finish up with a file.

Thats not too bad, I made a pair as for some reason this single cyliner engine needs to outlets.. Could have got a pair of these en eBay for 16 quid but thats not our way!

Next I need to work out how to make a tidy job of bringing together the two pipes in to one, I need to buy something so I bought a 180 degree bend.

This cost eleven quid delivered. I used a spacer to stand away from the pipe, you can see this under the ruler and balenced it against some blocks to keep it straight, marked with a sharpie and started cutting.

I can now weld these together to make a collector, these are a bigger size than the tube I will use to come from the manifold, they slip together nicely, time to get a move on with the manifolds.

Added the first parts, can’t go too far wrong here as long as they dont foul each other.

That all fits ok, slips nicely in to the collector we made earlier.

Needed to bring the 2″ pipe down to 38mm so I just squashed it in the vice, lined it up on the collector and drew round it then took the grinder to it and hey presto they did’nt fit, spent ages tinkering with my grinder to get a good fit but got there in the end.

There were a couple of other bends to play with to route it around the frame but you get the gist of it, none of it matches but I’m not bothered. Check out the sexy end can, it’s from a superduke 1290, it came from Mac’s Harley project and was very easy to unbolt whilst my daughter distracted him by throwing rocks at the front of his house.

I don’t have a seat kicking around and don’t feel like making one, I will at some point but not this time, I’ll check out eBay and see whats going like a budgie…cheep.

Loads to choose from, quite like some of the Chinese offerings but the flattish ones are all geared up to look like cafe racer style, what I would really like is something similar to an MTX50 seat, flat and rides over the tank by a few inches, very simple.

I have looked at too many seats and I’m getting bored, I’ll just get something I like the look of and worry about how to blend it with the tank later, my choice is from a 2016 Yamaha Tracer 700, taken from a showroom bike, 35 quid delivered and it’s mint.

There it is in all it’s glory, I have roughly cut a few cross braces from some left overs from a guttering job I did for my mum, thats all I could find, this gives me some idea of how to make a sub-frame.

I bent a length of tube very simply just to see where to go with this, starting to look like a fit.

A few tweaks on the bender and it’s starting to take shape!

Looks pretty tidy.

There it sit’s, I used some engineering string attached to the centre of the handle bars and lined that up with the centre of the rear tyre so I could eye up where to weld the subrame, the technology we use is mind blowing.

Starting to look alright, need to make another brace for the right side, feels odd to make the braces differently but this is the first single sided swing arm bike I have built.

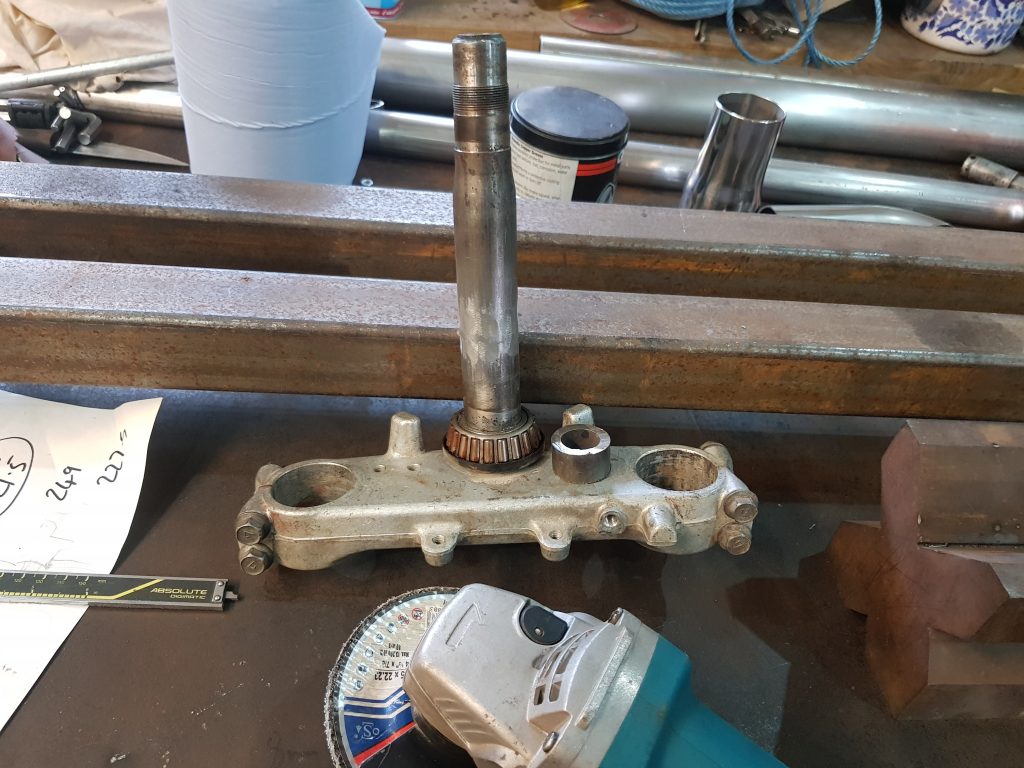

Been busily not doing much in the lock down, like most folk I guess, tinkering in the garden and more importantly doing a few bits to the XT project…. OOOHHH exciting I hear you cry! So, it’s about time I got this thing standing on it’s own two feet, I purchased a set of yokes on eBay from Legend-biking, they went missing as things do from time to time but I was sent a replacement set so I could continue, different year bike but I decided it would probably be ok, my mistake.. seems like the later models have a longer head stock tube, by about an inch so the newly arrived yokes wont fit…..ok I’ll chop a bit out of them and make these ones fit!

Before you say it, no I could’nt just wind down the nut further, the upper bearing is smaller so would not reach as the shaft widens. We, the Scavengers pride ourselves on our wide shafts and exposed nuts, rumour has it Mac’s nuts are CHROMED, I cry like a girly when I get caught by a stinging nettle so I’ll stick with my nuts as they are, standard.

There you go, a nice big straight shaft with a pot of lube in the background and a GRINDER…what the hell is happening!!!! I thought we were family friendly…..

Pretty happy, the front end is working as it should at this stage, time for me to give the back end a seeing too…..TEE HEE HEE…., honestly, a couple of beers and this place is going to ruin..

Here’s a sneaky peak so you can see what direction I’m heading in, Z400 tank from ’75 and straight’ish handle bars that I failed to return from the Last job I did for Mac, the tank cost me 35 quid plus postage on eBay, it does not fit well but is the shape I want so it’s staying, the seat is from 2016 and is an even worse fit but thats staying too, I really like it…just need to blend it all together, it’ll be fine, I have a plan!!